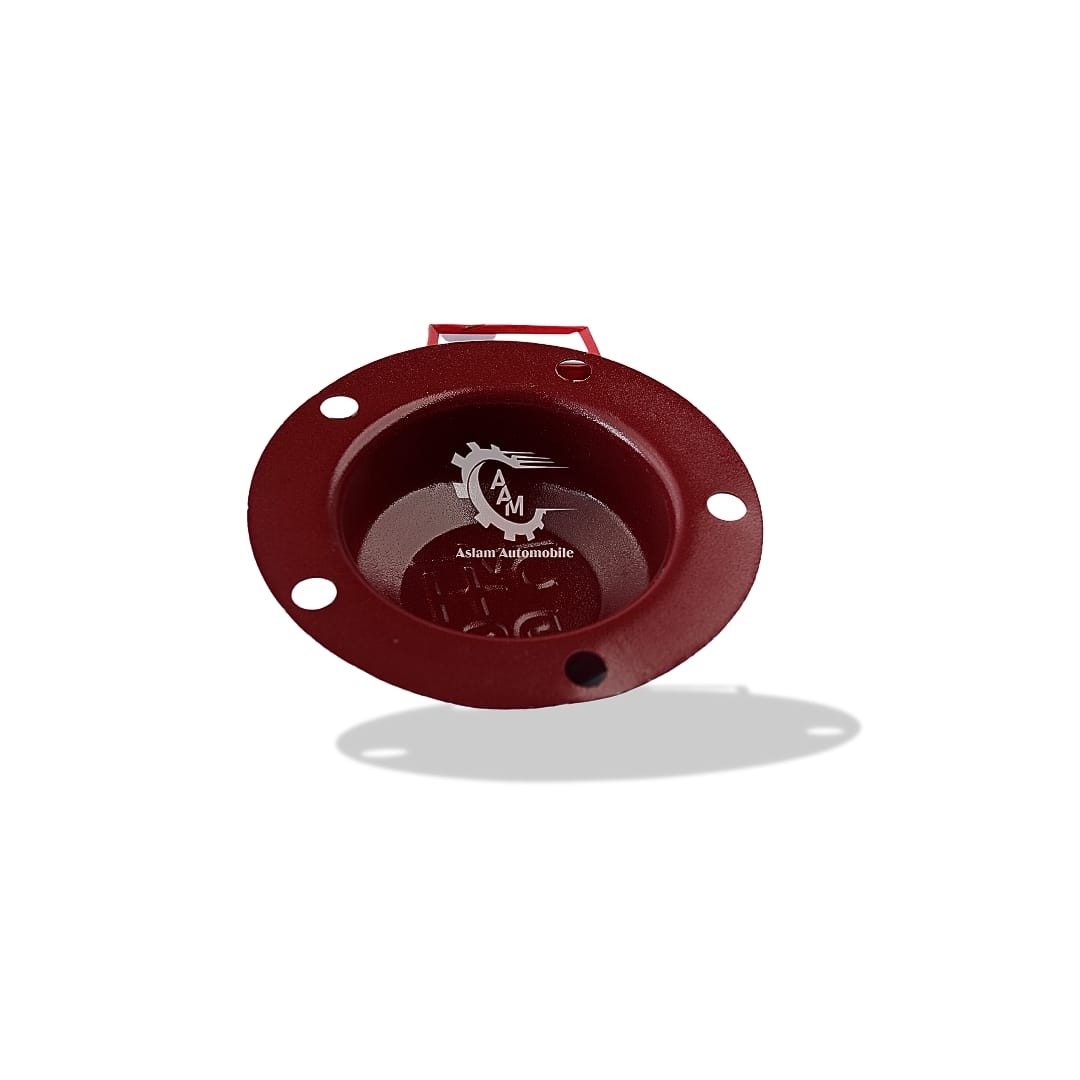

Star Washer Hino SG 1020

Inhouse product

Reviews & Ratings

Product Overview

The Star Washer for Hino SG 1020 is a durable and precision-engineered fastening solution designed to enhance the security of bolted connections in heavy-duty applications. Its unique locking design ensures optimal performance under high vibration, thermal stress, and dynamic loads, making it essential for the reliable operation of the Hino SG 1020 truck.

Key Features

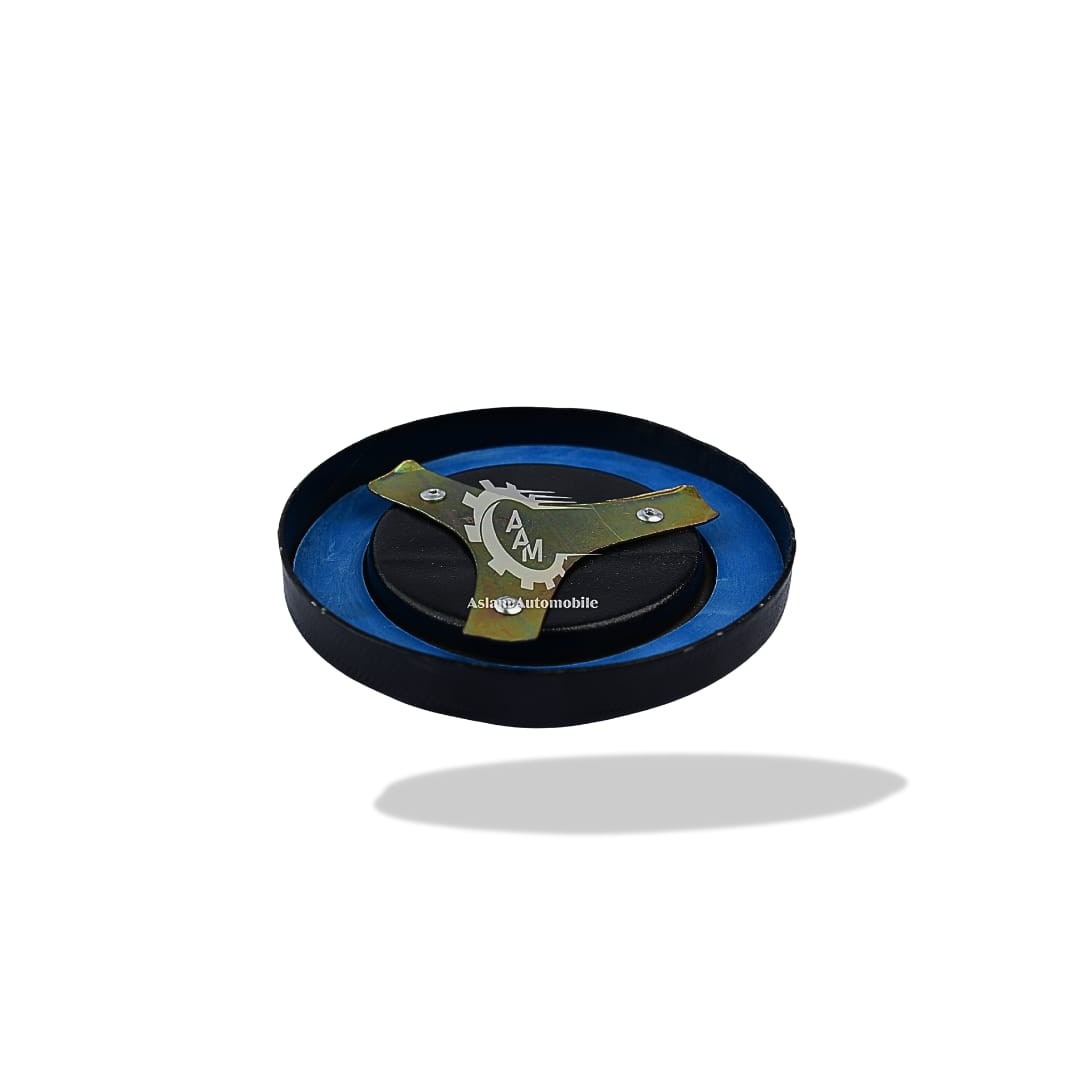

High-Performance Locking Design:

- Features radial teeth that grip both the fastener and mating surfaces to prevent loosening caused by vibration or torque.

- Suitable for critical systems, including engine, suspension, and chassis components.

Heavy-Duty Material:

- Constructed from hardened steel or stainless steel for maximum strength and durability.

- Coated with a zinc-plated or galvanized finish to resist corrosion and withstand harsh environmental conditions.

Exact Fit for Hino SG 1020:

- Specifically designed to match the fasteners used in Hino SG 1020 truck configurations.

- Ensures precise installation and long-lasting reliability.

Versatile Applications:

- Effective in securing fasteners in high-stress areas, such as drivetrain assemblies, exhaust systems, and structural connections.

Specifications

- Type: Internal tooth, external tooth, or combination (depending on application).

- Material: Reinforced steel or stainless steel with corrosion-resistant coating.

- Size: Designed to fit standard bolt sizes in Hino SG 1020 systems.

- Finish: Zinc or galvanized for enhanced protection against rust and wear.

Advantages

- Reliable Performance: Prevents fastener loosening in high-vibration environments, ensuring operational safety.

- Long-Lasting Durability: Resistant to deformation, corrosion, and wear, even in extreme conditions.

- OEM-Grade Quality: Meets or exceeds Hino’s original equipment specifications for the SG 1020 truck.

Applications

- Engine Components: Secures fasteners in high-temperature and high-pressure zones.

- Suspension Systems: Locks bolts in areas subject to heavy dynamic loads.

- Exhaust Systems: Maintains stability in components experiencing frequent thermal expansion and contraction.